AFCIs Come of Age

Photo © david.asch – Fotolia.com

Arc-Fault Circuit-Interrupters were the new kid on the block when they first appeared in the 1999 National Electrical Code (NEC). Since then, we have seen the technology advance to a new generation of devices, along with incremental expansion of the requirements for AFCIs in each new code edition. The next (2014) edition will continue that trend.

Why AFCIs?

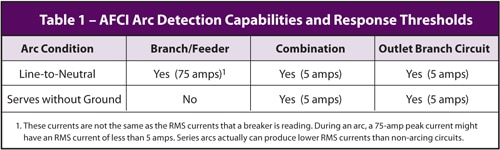

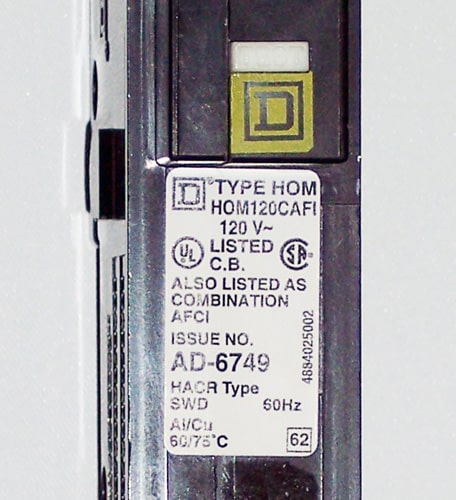

An arc results from an electrical current propagated through air. A common example of the discharge of electricity between electrodes is the spark plug in a car engine. Snap switches sometimes will cause an arc as the contacts make or break continuity, although arcs are momentary and rarely damaging. A sustained arc can occur at a loose connection or between conductors that have damaged insulation. These electrical arcs can produce temperatures of several thousand degrees while still drawing less current than is necessary to trip a conventional breaker (see Table 1). They are the origin of many house fires.

Approximately 13% of home fires are electrical in origin. The National Fire Protection Association (NFPA) estimates 46,500 residential electrical fires occurred in 2010, resulting in $1.5 billion in property losses, 420 deaths and 1,520 injuries. Of these fires, approximately half resulted from some type of arcing, whether in the structure’s wiring system or in the connected equipment.

AFCIs attempt to prevent these fires by interrupting the current when an arc is detected. The impetus for their development is described in a report developed by Underwriters Laboratories (UL) for the Consumer Product Safety Commission (CPSC) in 1995. The report, Technology for Detecting and Monitoring Conditions that could Cause Electrical Wiring System Failures, recommended the development of AFCI technology as a means of reducing home electrical fires.

One of the challenges in development of AFCIs was to create a product that detected and interrupted current when a dangerous arc occurred, and that did not “nuisance trip” on an arc that was not dangerous, such as the one that occurs frequently at snap switches. AFCIs accomplish this by looking at the electronic “signature” of an electrical arc (see Figure 1), which includes a sequence of current spikes and voltage drops.

Figure 1 – Voltage and current arcing signature

Why doesn’t an ordinary breaker trip?

When an arc occurs, the instantaneous peak current can be very high, with temperatures of several thousand degrees. However, the peak current has a short duration in relation to the full 60-Herz cycle. The circuit breaker reads the averaged heat over each full cycle of current rather than the concentrated heat that occurs at the point of the arc. The breaker might think that a very low current is being drawn. It doesn’t see the arcing fault as different from other load and as long as the current is within the breaker’s rating, it does not open the circuit.

Types and limitations of AFCIs

UL 1699 recognizes six categories of AFCIs:

- Branch/feeder types (AVZQ)

- Combination types (AWAH)

- Cord types (AWAY)

- Outlet circuit types (AWCG)

- Outlet branch-circuit types (AWBZ), and

- Portable types (AWDO)

For practical purposes of inspecting what we see in the field (or will see in the near future), the three types with which we are concerned are the branch/feeder, combination and outlet branch-circuit type.

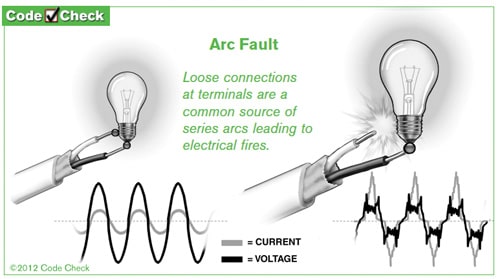

Figure 2 – Branch/feeder AFCI label

Photo courtesy of Douglas Hansen

Branch/feeder AFCIs were the first generation of protection. They were listed by UL as circuit breakers and also “classified” as branch feeder AFCIs (see Figure 2 above). This type is no longer permitted. Limitations of the branch/feeder type include inability to detect series arcs, such as a loose connection, and relatively high levels of fault current to activate the device (see Table 1). If a dead short at the outlet had sufficient resistance that it could not produce at least 75 amps of peak current, the device might not trip. Receptacle outlets on 15-amp circuits almost always have that amount 44 of available fault current. The appliances at the end of a cord do not necessarily have that amount. These limitations restricted the ability of branch/feeder AFCIs to detect arcs in connected equipment such as space heaters and electric blankets. The main value of branch/feeder AFCIs was protection against (relatively uncommon) parallel arcs involving the hot and neutral conductors of the circuit.

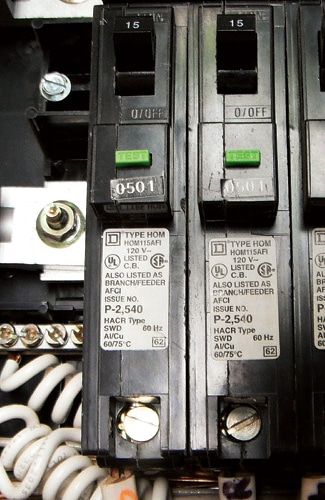

The second generation of AFCIs is the combination type (see Figure 3 below). The term derives from its ability to detect a greater combination of potential arcing conditions. It has nothing to do with having a ground-fault protection function (more on that later). Since January 1, 2008, all AFCI breakers are required to be combination types. They detect arcs that would activate a branch/feeder AFCI as well as series arcs, which branch feeders cannot detect. The third type is the outlet branch-circuit type. These look similar to GFCI receptacles and have essentially the same performance characteristics as combination-type AFCIs.

Figure 3 – Combination AFCI label

Photo courtesy of Douglas Hansen

The ability to detect a series arc that is not directly to the equipment-grounding conductor is the critical factor. A loose connection such as an improperly tightened terminal on a receptacle or a loose wire nut is a much more likely source of an arc than a line-to-neutral arc, which must involve both current-carrying conductors of the circuit. We see that both the combination and outlet branch-circuit types are capable of detecting these much more common arcs.

AFCIs cannot detect a “glowing” arc. A high-resistance connection through a conductor sometimes can reach conditions that will ignite adjacent combustible material, and AFCIs will not prevent this. UL states that AFCIs will mitigate the potential effects of electrical arcs, not that they will eliminate them

Outlet branch-circuit types

An outlet branch-circuit type AFCI (see Figure 4 below) is a device with feed-through connections and an integral receptacle. In that regard, it is similar to a GFCI receptacle. It is intended as the first outlet on a branch circuit that otherwise does not have combination AFCI protection. Under the present (2011) NEC, this device is permitted when the wiring between an ordinary circuit breaker and the first outlet of the circuit is metal-clad (rigid metal conduit, intermediate metal conduit, electrical metallic tubing, MC cable or steel-type AC cable).

Figure 4 – Listed outlet branch-circuit type AFCI device

Photo courtesy of Pass & Seymour Legrand/ IAEI

Since these are permitted by the code in some circumstances, you might wonder why you haven’t seen one yet. Though the manufacturers have patented these, the current restrictions in the code severely limit the market for these devices. It simply wouldn’t be cost-effective to produce them yet. That may change in 2014. The 2011 edition of the NEC requires that all replacement receptacles in areas presently requiring AFCI protection be provided either with AFCI protection upstream (such as at the breaker) or be replaced with outlet branch-circuit-type AFCIs. That requirement goes into effect January 1, 2014.

Ground fault detection

AFCI circuit breakers look just like GFCI breakers when you first see them. They have the familiar coiled wire that connects to the neutral bus in the panelboard, and they have a similar test button. The branch-circuit neutral conductor connects to the AFCI breaker rather than directly to the neutral bar.

In fact, most AFCIs also have ground-fault detection built into them, though not at the level that would qualify them as Class A GFCI protection. The type of Class A GFCI we are accustomed to in our homes is required to trip when a current imbalance of 6 milliamps exists between the hot and neutral conductors. That is well below the level at which a person being shocked would reach the “let go” threshold of involuntary muscle contraction or the level of ventricular fibrillation (electrocution). The ground-fault detection of AFCIs is voluntary on the part of the manufacturers and generally is set at 30 milliamps. This does not qualify as a replacement for a Class A GFCI.

There are some types of equipment that require GFPE – Ground Fault Protection of Equipment – at the 30 milliamp level. Outdoor receptacles on a branch circuit dedicated solely to electric snow-melting or de-icing equipment are exempt from GFCI requirements, though the equipment does require GFPE. In some jurisdictions, an AFCI breaker might be deemed acceptable for this protection, though it would be a matter of interpretation by the local jurisdiction since AFCIs are not listed as GFPEs. (Some branch/feeder AFCIs are marked with a 30mA ground-fault detection level.)

Multiwire circuits

A multiwire circuit in residential wiring is a pair of 120-volt circuits that share a common neutral conductor. When these circuits are wired with NM cable, they are readily identifiable by having a black, red and white wire. Multiwire circuits have been used in house wiring since the days of Thomas Edison. To this day, they still are called Edison circuits by some electricians. Multiwire circuits save money in cable cost and actually provide greater efficiency. Because the neutral conductor carries only the imbalanced load difference between the two hot conductors, the voltage drop is lower than it would be with individual neutrals.

Ground-fault detection leads to a limitation on use of AFCIs. If ordinary AFCI breakers are installed on a multiwire circuit, they trip as soon as loads are applied. The amount of current on the neutrals will not match the amount of current on the hot conductors. We have seen this problem a number of times on renovations and panel upgrades to existing houses. At times, the contractors don’t seem to know this because they haven’t yet applied a load to the circuit and don’t realize that the breakers will trip as soon as someone does plug in a light or appliance. They sometimes blame the AFCI for “nuisance tripping” when it was performing as intended.

Only four large manufacturers of circuit breakers remain in the United States market, and each has its own strategy for AFCIs on multiwire circuits:

General Electric has a line of breakers that will work with multiwire circuits because they disable the ground-fault function of the breaker. The breakers that are suitable for this application have a MOD 3 suffix on the breaker rather than the usual MOD 2. GE instructs that a handle tie be applied first (something required now for all multiwire branch circuits formed from individual single-pole breakers) and that both of the pigtail neutrals be connected to the neutral bus. The branch-circuit neutral then is connected to one of the breakers, not to both. It doesn’t matter which one. GE also cautions that the breakers lack an internal trip. The handle tie enables the two breakers to be simultaneously disconnected, though if one breaker trips from a fault it might not automatically trip the other breaker unless the handle moved sufficiently.

Eaton, the parent company of Cutler Hammer, sells a 2-pole combination breaker suitable for multiwire circuits for both its BR (1-inch wide) line as well as the CH models (3/4 inch wide). Unfortunately, it continued to sell its branch/feeder 2-pole breakers well past the time when they were no longer permitted under the NEC.

Square D so far has not manufactured a 2-pole AFCI for either its QO or Homeline series.

Siemens makes a 2-pole AFCI that includes indicator lights that will tell you if it has tripped from an arc fault or a ground fault, as well as test buttons for each pole (see Figure 5).

Figure 5 – Siemens 2-pole AFCI

Photo courtesy of Siemens

Code issues – locations requiring AFCI protection

The NEC provides an ever-expanding list of the circuits and devices that require AFCI protection. Not all states and cities adopt these portions of the NEC. Pressure from builders’ groups and others have left many areas lagging behind the NEC, and it is always best to learn the rules that apply in your area.

Section 210.12(A) of the 2011 NEC requires that all 15- and 20-amp branch circuits have protection for the entire branch circuit when that circuit has outlets in dwelling family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways or similar rooms or areas. What doesn’t that cover? For the most part, the areas left off that list (garages, exteriors, bathrooms, kitchens and laundries) have requirements for GFCI protection, though not for 100 percent of the outlets in those rooms. Remember that the term “outlet” as used in the NEC means more than just receptacle outlets. An outlet can be a lighting outlet or another point on the circuit where electrical equipment is supplied with current. Hard-wired smoke alarms are outlets and require AFCI protection. To some, that seems counterintuitive (potentially disabling the circuit that powers a warning device). However, smoke alarm circuits have caused fires in attics and modern smoke alarms have battery backup power.

The locations listed above require combination type AFCI protection, not the branch feeder type. The exception is the previously mentioned allowance for an outlet branch-circuit type AFCI at the first outlet with a metal-clad wiring system between it and the panel. Until those devices are manufactured, the exception is moot at this time.

Another exception allows an individual branch circuit for a fire alarm system. This exception is for central-station fire alarms, where the branch-circuit breaker is accessible only to qualified persons per sections 750.41(B) and 760.121(B) and where a metal-clad wiring system is used.

Extensions, modifications or replacement of existing branch circuits in the areas requiring protection triggers a need for AFCI protection either by a combination-type breaker at the origin of the branch circuit or an outlet branch-circuit type AFCI at the first outlet of the circuit; see 210.12(B).

Section 406.4(D)(4) covers replacement receptacles. In areas that are listed above, these will require AFCI protection beginning January 1, 2014. The protection can be provided either by a combination AFCI breaker or by an upstream outlet branch-circuit AFCI or by an outlet branch-circuit AFCI receptacle.

Several proposals for the 2014 NEC call for the upstream outlet branch/feeder AFCI to be in an accessible location. It also appears likely that AFCI protection will be required 44

in 2014 for all 120-volt circuits that have any outlet in a laundry room or kitchen. Another proposal calls for AFCI protection of an exterior light circuit when the switch for it is located in a room where the circuits require AFCI protection.

What could go wrong?

When Code-Making Panel 2 decided to endorse the idea of AFCI protection for bedroom receptacle outlets in the development of the 1999 NEC, it was clear that this was only a small step toward an inevitable expansion of the rules for AFCIs. The panel’s analogy was that it was much the same as mandating seat belts and that it had to start somewhere. Therefore, the first generation of AFCIs was a learning opportunity both for the manufacturers and for installers. The great expansion of required areas of AFCI protection did not come about until the second generation of AFCIs had come into being; product improvements and expanded code requirements go hand in hand.

One of the issues found with the first-generation AFCIs was an increase in the amount of heat given off by the breaker. Since these devices are monitoring the circuit and include electronic circuitry that is constantly energized, some residual heat is expected. According to the manufacturers, this has not been so extensive as to cause any performance issues, and they claim that the combination AFCIs do not have this issue to the same extent as the first generation AFCIs. UL has performed testing for this issue and confirms that the amount of heat is not so excessive as to exceed either the UL standard for breakers (UL 489) or the standard for panelboards (UL67).

In November 2004, Square D announced a recall of 700,000 of its AFCIs. A malfunction in their test button could fail to activate the AFCI circuitry. As a result, the breakers would act like nothing more than (much cheaper) non-AFCI breakers. The recalled breakers had a blue test button. Square D changed the color of the test button in subsequent breakers. The breakers in the recall were branch/feeder types that do not meet present code.

Many contractors reported nuisance-tripping issues with AFCIs. This problem seemed to be more widespread after the 2002 NEC expanded the application of AFCIs to include lighting circuits. One cause of this problem could be the electrician’s fault. If the neutrals of more than one circuit are joined together in a box, current will have more than one path to return to the panelboard and the ground-fault sensing of the AFCI will cause the breaker to trip. Neutrals should not be joined with those of other circuits except inside panelboards, yet many electricians have been lazy about this issue when wiring up multi-gang switch boxes. It is essentially another version of the problem with using AFCIs on multiwire circuits.

Another aspect of nuisance-tripping occurred with some early AFCIs that also had GFCIs on the same circuit. That issue appears to have been resolved with the combination type AFCIs. Part of the UL testing of an AFCI breaker includes placing GFCI outlets on the same circuit.

AFCI breakers always are full width. Many panels have provisions for installing either a tandem breaker or a single breaker on a single bus stab. Tandem breakers allow two circuit breakers in the same space that otherwise would be occupied by one breaker. Some panels have a specified number of bus spaces where tandem breakers are allowed and other bus spaces that accept only full-size breakers. You might see a 150-amp panel that is rated to have 30 branch-circuit breaker poles, yet has only 20 bus stabs. In that case, the label will state that 10 of them are designed for full-sized breakers and include a feature that will reject tandem breakers and 10 of them allow tandem breakers. Thirty breakers are therefore possible on such a panel (20 tandems and 10 full-size breakers). What happens when the electrician pulls all of his circuits back to that panel, then discovers that he must use AFCIs where he had planned on using tandem breakers? Since the AFCIs always are full size, he may find that the panel is no longer large enough for all these circuits as it only has room for 20 full-size breakers.

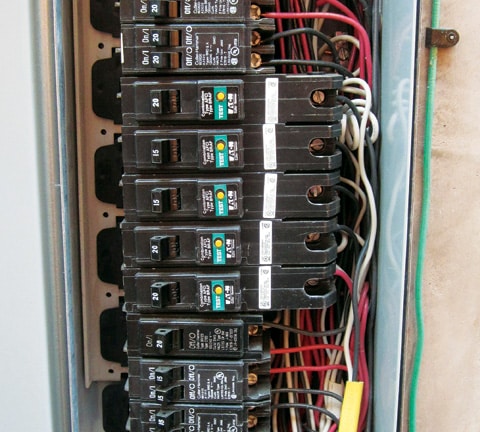

With some brands and models, AFCIs take up not only a full breaker slot, they also take up some of the gutter space in the panel. Square D and Eaton AFCI circuit breakers are almost twice the length of their ordinary breakers. The result is that the neutral bar cannot be seen unless the breaker is removed, and the wiring space of the panels becomes much more crowded (see Figures 6 & 7).

Figure 6 – Square D AFCIs

Photo courtesy of Douglas Hansen

Figure 7 – Eaton AFCIs

Photo courtesy of Douglas Hansen

AFCIs and older homes

AFCIs are not available for many of the older panel types, such as Federal Pacific, Zinsco or the many regional products and old designs still in use. While it might be possible to partially retrofit such systems with outlet branch-circuit AFCIs, a more efficient approach is to replace the panel with one of the modern types that are available. Some panelboard makers (e.g., Eaton) make replacement panelboards that can fit inside the enclosure of an old Federal Pacific that is the full width of a stud bay.

AFCIs might seem like an ideal product to recommend for houses with knob and tube wiring, or with old-technology aluminum wire (1964 – 1973). It is possible that these systems would benefit from the added safety of AFCIs, although we caution against thinking of these as a magic bullet or an excuse to avoid repairing any obviously hazardous situations. If there are problems with aluminum wire terminations or with deteriorated knob and tube wiring, the known issues should be repaired first. In some cases, AFCIs then can be added to older homes. Remember that most knob and tube systems use multiwire circuits, which create another set of limited options for compatibility with AFCIs.

Conclusions

Ten years ago, we wrote an article on AFCIs and called them a “technology driven by the codes.” At the time, the manufacturers were catching up to requirements that were not yet in effect. Today, the situation is reversed, with technologies such as outlet branch-circuit AFCIs being ready before the codes have mandated them.

AFCIs are here to stay. From their origins in the UL report to the CPSC back in 1995, we have seen improved product development and increased code acceptance to the point where we expect to someday see requirements for AFCI protection at all 120-volt circuits in a home. Yet, the report back in 1995 did not make the development of this technology its primary recommendation. In fact, that was number three on the list. Number one was to promote the electrical inspection of older dwellings to identify flagrant hazards in need of correction. Number two was to stimulate the repair and correction of those hazards. The chances of an electrical fire rise dramatically with the age of the home, and the best prevention is competent inspection and repair of electrical hazards.

————————————————————————————–

Code History

1999:

The first mention of AFCIs is in the 1999 NEC. Section 210-12 required them for protection of branch circuits having bedroom receptacle outlets. The requirement did not become effective until January 1, 2002. This small first step gave manufacturers and builders a chance to get ready to implement AFCI protection.

2002: Section 210.12(B) required AFCI protection for circuits with any outlet in a bedroom, not just receptacle outlets. These circuits include any with outlets for lighting or smoke alarms in bedrooms.

2005: Section 210.12(B) required that the AFCI be a combination type, while allowing branch/feeder types to be used until January 1, 2008. By then, the recession had begun, and manufacturers had years of backlogged stock of old branch/feeder types. Despite the code, they remained on the market well into 2010. The 2005 NEC also was the first to acknowledge the possibility of locating the AFCI protection other than at the origin of the branch circuit, allowing it to be 6 feet from the panel without specifying what kind of device could possibly comply. Section 760.41 introduced a prohibition on installing AFCI protection for fire alarm circuits within the scope of article 760.

2008: Section 210.12(B) expands the required areas of AFCI protection to include circuits with outlets in dwelling family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways or similar rooms or areas. Branch/feeder AFCIs no longer are allowed. The requirements prohibiting AFCIs on fire alarm circuits are included in 210.12(B) Exception 2 and are harmonized with article 760. The distance limitations are removed for situations where the AFCI protection is not at the panelboard, and the list of metal-clad wiring methods is created for those situations. The NEC still calls for all protection to be combination type, so outlet branch-circuit types still are not recognized.

2011: The types of rooms for which the circuits require protection does not change. Section 210.12(B) is renumbered as 210.12(A), and a new section (B) deals with branch circuit extensions and modifications. Outlet branch-circuit types of AFCIs are recognized in both 210.12(A) and in Article 406 – Receptacles. Section 406.4(D)(4) requires replacement receptacle outlets to comply with the AFCI requirements for their locations, and this can be achieved with outlet branch-circuit types.

2014: We anticipate that AFCI protection will be required for all 120-volt circuits having outlets in kitchens and laundries, and that AFCI devices will be required to be readily accessible.

————————————————————————————–

Testing AFCIs

Just as with GFCIs, there is no shortage of instrument makers willing to provide external “testers” for these devices. UL emphatically denies that these instruments are testers even when the instrument carries a UL listing. UL evaluates outlet testers for safety, not for performance, so the UL insignia has nothing to do with whether it can accurately test an AFCI. UL states that these devices are “indicators” and not “testers.” For further information, read: www.iaei.org/files/2005/05/afci-testers-not-really.

One of the earliest AFCI “testers” was the ETCON model AF120, and it looked similar to ETCON’s orange GFCI “tester” except that it was green. That product placed a connection between the hot and ground, intended to draw 30 milliamps and trip the breaker based on its GFPE function. Because these were mislabeled as AFCI “testers,” they were subject to a product recall.

The AFCI testing performed by UL in its laboratories is a whole different matter. It does this under conditions that actually create (not just simulate) an arc, and AFCIs must pass those UL tests to gain their listing. The built-in test button on an AFCI tests whether the circuitry is functional, and it is the only valid field test. An inspector who finds an AFCI that is non-responsive to his hand-held tester has not necessarily found a defective AFCI. What matters is whether the built-in test button tripped it, and whether it properly reset after it was tripped. With most AFCIs, you need to turn them the rest of the way to the “off” position, then back to “on.”

————————————————————————————–

Acknowledgments: Thanks to Jim Katen for his editorial and technical assistance. David Dini of Underwriters Laboratories was the project manager of the original study prepared for CPSC and also chaired NPFA’s Aging Wiring Research Project. James W. Carpenter was chairman of Code Panel 2 during the 1999 NEC cycle. The first requirements for AFCIs came about under his vigorous leadership.

To Read the Full Article

ASHI offers its members unparalleled resources to advance their careers. ASHI offers training for inspectors at all levels of knowledge and experience, including resources about all major home systems. Members benefit from a vast network of experienced professionals, providing a community for mentorship and knowledge sharing..

In this Issue

FIND A HOME

INSPECTOR

Professional Networking

Grow your professional network, find a mentor, network with the best, and best part of the community that’s making home inspection better every day.