Technical Focus: Service Entrance Conductors

The electrical system is a critical part of a home. The home inspection should include the overhead service drop or underground service laterals and the service entrance conductors. The utility company is responsible for the overhead service drop or underground service entrance (service laterals). The homeowner is responsible for all electric components beyond the connection of the laterals or the service drop.

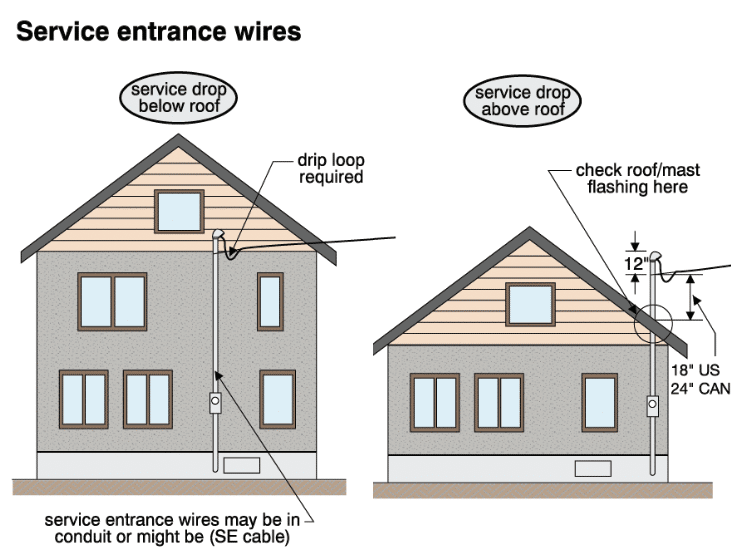

In this article, I will focus on overhead services rather than service laterals, and I will address service entrance conductors rather than service drops. The service entrance conductors connect with the overhead service drop wires, typically at the drip loop. The transition from utility responsibility to homeowner responsibility is called the service point. The service entrance conductors extend down to the service equipment (main disconnect, service panel, service box, distribution panel). The electric meter is typically the first component between the service point and the main disconnect.

The service conductors for a typical 240-volt service include two black wires, each energized at 120 volts. These are often referred to as hot or ungrounded. There is also a white wire, which is neutral (grounded). They may be part of a service entrance cable (SEC) or they may be in a service entrance conduit, which is known as the service mast.

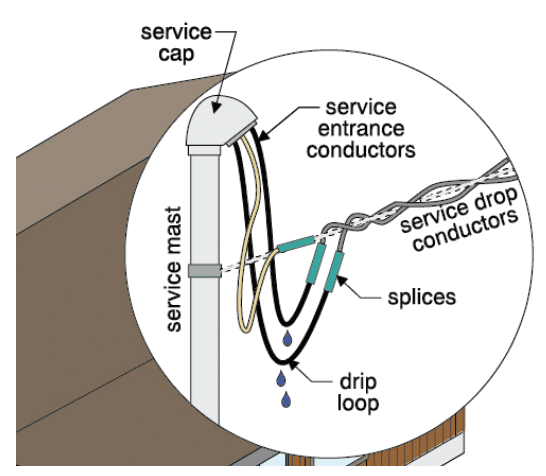

Many jurisdictions require the service entrance wires to extend at least 30 inches out of the service cap (entrance cap) at the top of the SEC or masthead. This gives the utility enough room to make their connections and leave a drip loop.

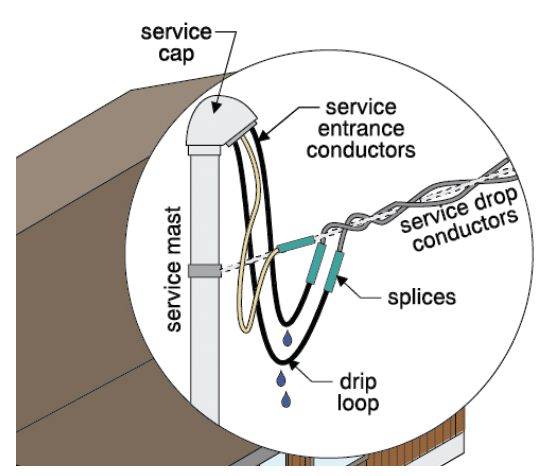

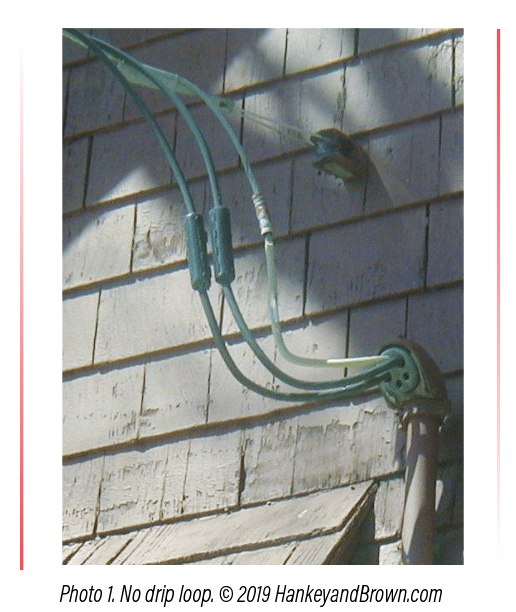

The drip loop is simply a low point in the wires where water can drip off rather than run down inside the conduit or masthead and into the service box. A drip loop also shows that the service drop wires are supported properly, and that there is no tension on the splices between the service drop and service entrance wires.

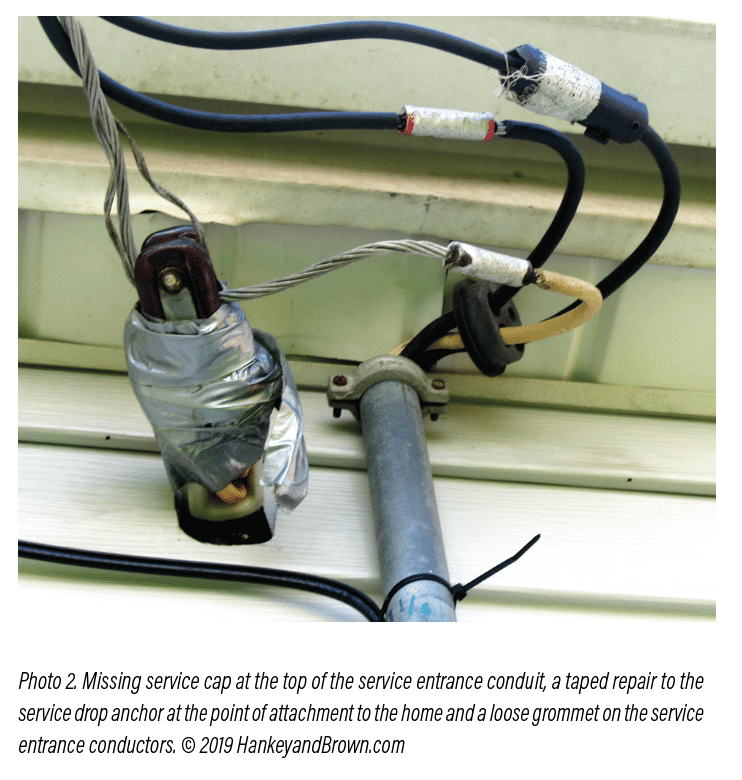

A service cap at the top of the mast provides a weather-resistant point for the service conductors to enter the conduit or mast. (See illustration top of column to the right.) The service cap may also be called a weather head, entrance cap or gooseneck in the case of an SEC.

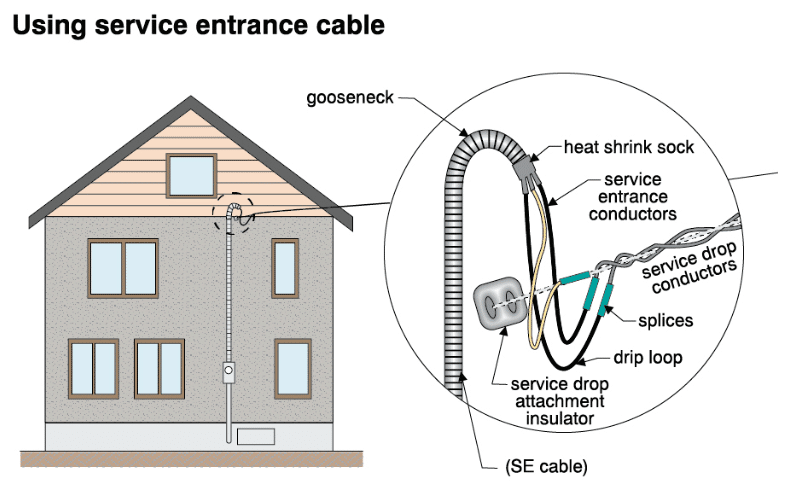

A drip loop should be provided whether there is a mast above the roofline or a conduit or cable below the roofline. The minimum height of the drip loop above a roof may be 18 inches to 10 feet, depending on several criteria and on jurisdiction.

Where an SEC is used without conduit or masthead, the cable itself is bent downward (like a candy cane or gooseneck) before connecting to the service drop wires. This discourages water entry into the cable between the wires and the exterior sheathing.

Using Service Entrance Cable

The service entrance conductors may be in a conduit on the outside of the building or there may be a special SEC that does not require a conduit. Either situation is acceptable.

Some service drops are attached to the side of a building. Here, the conduit will extend up the building and terminate in a service cap below the roofline.

Where the service drop wires are above the roofline, a service mast is required. This mast extends up through the roof and terminates in a service cap. This mast is often a conduit that contains the service entrance wires. It is also the mechanical support for the service drop wires. Depending on the height of the mast, guy wires may be necessary to hold the mast straight. The weight of the service drop wires is significant and poorly supported masts can be bent or even broken.

The mast must be properly flashed where it penetrates the roof. The service drop conductors are typically attached to the mast within about 12 inches of the top. The service conductors should not be too close to the roof, as previously mentioned.

Service Entrance Wires

Standards of practice typically require the inspector to report the service size (amperage and voltage rating). Based on the gauge of the conductor, you may be able to determine whether you have conductors rated for a 60-amp, 100-amp or 200-amp service, for example. Note: The gauge of the service drop conductors may not be a good indicator of the service size because they are often smaller than the service entrance conductors.

Meters are nearly always sealed by the utility to reduce the potential for tampering or theft of power by jumpering the meter. Home inspectors should not break utility seals.

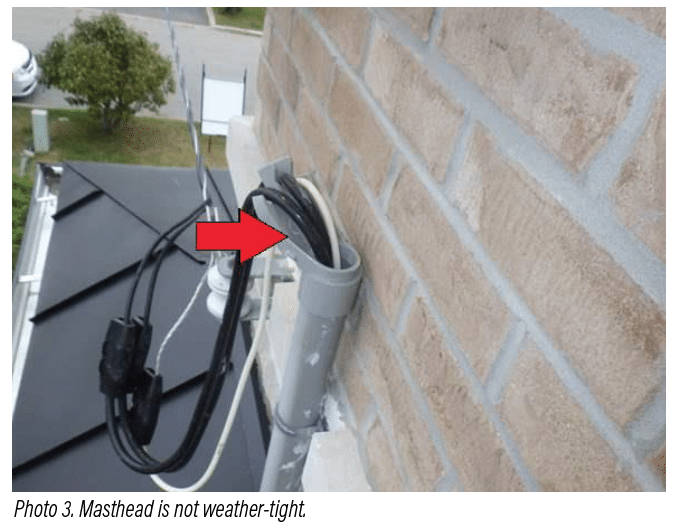

It is important to examine the connections above and below the meter to determine if they are secure and weathertight. Water making contact with electrical equipment can create several problems, including corrosion, overheating and fire. Furthermore, a loose or damaged mast increases the potential for damage to the insulation on the conductors caused by movement.

CONDITIONS

No Drip Loop: This is usually an installation problem, although it may be the result of a failed support for the service drop. The implications are water entry into the electrical system and possible mechanical stresses on the wires and splices. Look for the service entrance wires to have a low spot where they connect to the service drop wires. The wires should be visibly slack. See Photo 1.

No Masthead or Service Cap (Entrance Cap): This is usually an installation defect and the implication is that water can get into the electrical system. Make sure there is a weather-tight cap on the conduit or mast. This should be arranged so that conductors enter the underside of the cap. See photo 2.

Masthead Not Weather-tight: Sometimes a masthead (service cap) is present, but loose or at an improper angle. It should be weather-tight. This is usually an original installation problem, although mastheads may have worked loose or out of position. These conditions increase the potential for water entering the electrical system. See Photo 3.

Conductors Too Close to the Roof: The bottom of the drip loop should be well above the roof. In the United States, the requirement is at least 18 inches. In Canada, it is 24 inches. Local authorities may require more height where snow and ice occur, for example. The mast is too short in Photo 4; notice that the conductors are laying on the roof.

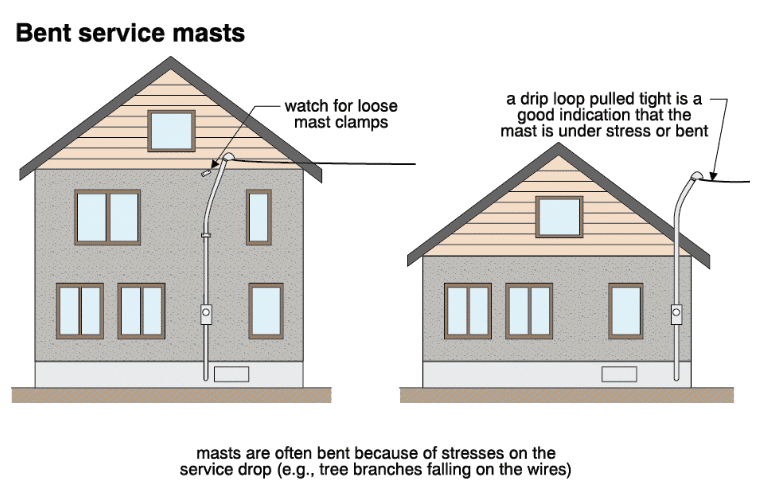

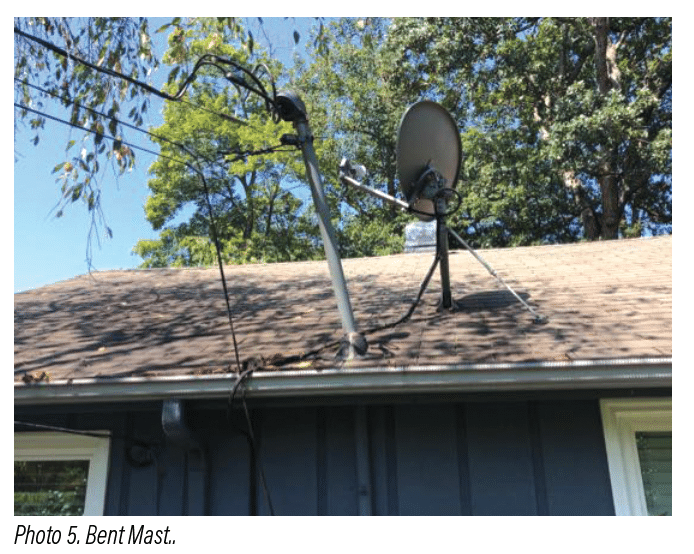

Mast or Conduit Bent: The masts or conduits should be straight and, in most cases, vertical. Masts or conduits may be bent by the stresses exerted by service drops. If the service drop wires are not well secured by the building, they may pull the mast or conduit. Where the service drop wires are supported by the mast, failures may occur if the mast is not properly secured with a guy (guy-wires).

Masts or conduits may be loose because the mechanical fasteners or clamps have failed. There are many reasons for this, including rust, rot and inappropriate connectors.

Bent Service Masts

The conductors may sag, reducing overhead clearance, or they may fall, creating a dangerous situation. Weather-tightness may also be lost.

Make sure the masts and conduits are not bent or pulled out of position. Look at clamps for evidence of movement. Masts taller than 5 feet should have guy-wires. Where there is a mast, look at the roof-flashing connection to see if it has been displaced. See Photo 5.

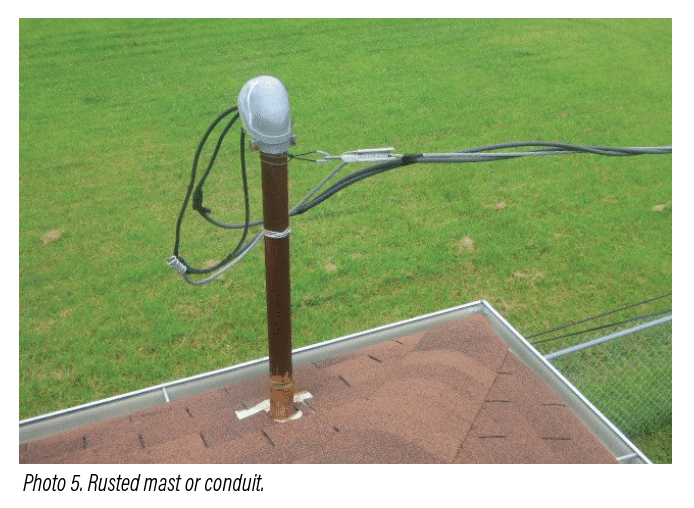

Mast or Conduit Rusted: Rust may be the result of age or the use of inappropriate materials. The implications are mechanical failure, allowing wires to fall and water entry into the electrical system.

Look for rust at electrical connections. Rust is most likely to occur at horizontal surfaces where water may collect. Pay particular attention to threaded connections where the pipe walls have been made thinner by cutting threads into them.

It’s helpful to distinguish between surface rust and rust that compromises the strength of the mast or conduit. Surface rust may be identified by flaking rust that reveals sound metal below. In some cases, scraping and coating with a rust-preventive paint may be adequate. Don’t touch the systems or probe with a screwdriver during a home inspection. Recommend further investigation and improvement as necessary.

Mast Rotted: Rot is common on wooden masts, particularly near horizontal surfaces where water may accumulate and near roof flashings. Wood masts are not allowed on new work in many areas. The implications are a loss of strength of the mast and collapse of the wires. Look carefully at wooden masts for rot or insect damage.

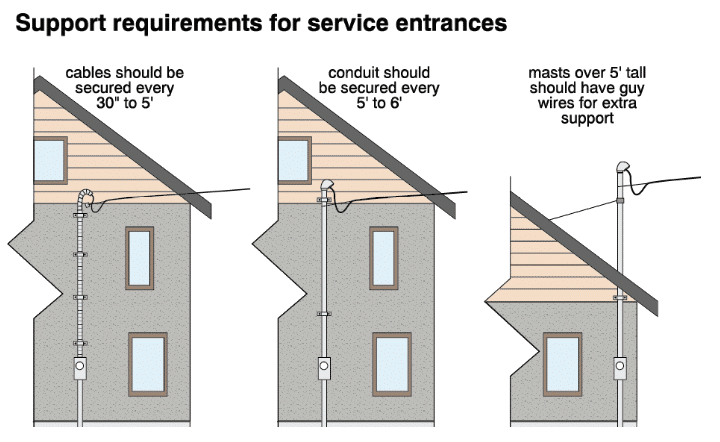

Mast, Conduit or Cable Not Well Secured to the Building: Depending on the material, conduits are usually secured to the building every 5 to 6 feet along the building wall. Masts extending more than 5 feet above the roof are typically secured with a guy-wire. SECs should be secured every 30 inches to 5 feet, depending on the cable type (and according to the manufacturer’s recommendations).

Support Requirements For Service Entrances

A poorly secured mast, conduit or cable may be an installation issue or the result of a fastener failure. The mast, conduit or cable may pull away from the building, resulting in fallen wires and a dangerous situation. Open joints will allow moisture into the electrical system. Look for evidence of movement or failure of connectors.

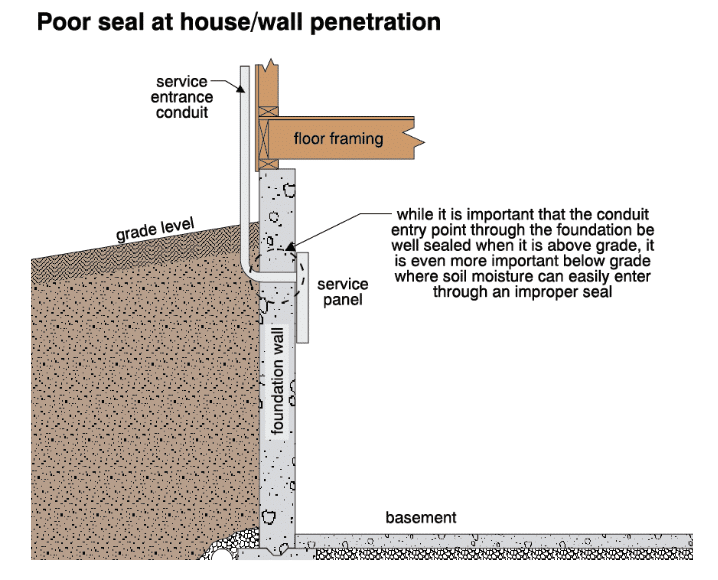

Conduit or Cable Not Well Sealed at House Wall Penetration: This may be a maintenance problem or the result of poor installation. The implications are water getting into the electrical system. If it’s visible, make sure the wall or conduit junction is well sealed.

In rare cases, the conduit or cable may enter the house below grade. You won’t be able to see whether the conduit is well sealed where it goes through the wall. You’ll have to look for evidence of leakage inside when looking at the service equipment.

Poor Seal At House/Wall Penetration

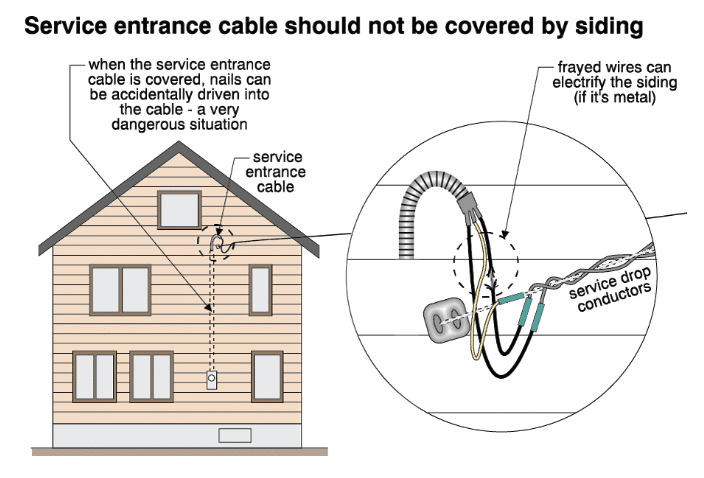

Service Entrance Cable Frayed, Damaged or Covered by Siding: Cable or conduit should not be frayed, damaged or covered by siding. The cable may be damaged or frayed if it is allowed to move in the wind or if tree branches rub against the cable. These cables are also vulnerable to mechanical damage by ladders, for example.

Cable covered by siding is an installation problem. This can create a dangerous electrical condition. Anyone touching the cable could get a shock. If live portions of the cable touch metal siding, the entire skin of the building could become electrically charged. If the cable is covered by wood siding, for example, driving nails through the siding creates a shock hazard.

Service Entrance Cable Should Not Be Covered By Siding

Where an SEC is used, carefully check its condition. Make sure it is accessible and visible over its entire length. Some authorities allow conduit to be run behind brick siding, for example, because the wires are protected from damage. Cable, however, should never be buried.

CONCLUSION

The service entrance conductors and ancillary equipment are the responsibility of the homeowner rather than the utility company. As with all electrical components, the potential for shock, flash or electrocution exists. Careful inspection is required and inspectors should take care to avoid touching energized portions of the system. When in doubt, recommend a specialist.

For more information on electrical systems and all things home inspection, refer to the ASHI@HOME training program.

Alan Carson is a Past President of ASHI and President and co-founder of Carson Dunlop (www.carsondunlop.com).

Thank you to ASHI member Roger Hankey for his invaluable contributions to this article.

To Read the Full Article

ASHI offers its members unparalleled resources to advance their careers. ASHI offers training for inspectors at all levels of knowledge and experience, including resources about all major home systems. Members benefit from a vast network of experienced professionals, providing a community for mentorship and knowledge sharing..

In this Issue

FIND A HOME

INSPECTOR

Professional Networking

Grow your professional network, find a mentor, network with the best, and best part of the community that’s making home inspection better every day.