Pressure-Reducing Valves on Hot Water Heating Systems

Hot-water boilers are popular in many parts of the country and are becoming more popular where people are looking to use hot-water radiant heat (also known as hydronic heating systems). The popularity of wall-hung boilers and wall-hung boiler/water heater combination units is also on the rise.

The pressure-reducing valve (also called the automatic make-up valve or the feed-water pressure regulator) connects the house’s plumbing supply system to the boiler water. It is designed to automatically add water as needed to the system to maintain the desired pressure (12-15 psi when the system is at rest and the water is at room temperature) rather than the supply plumbing pressure, which may be 60 psi. It is an operating control rather than a safety control.

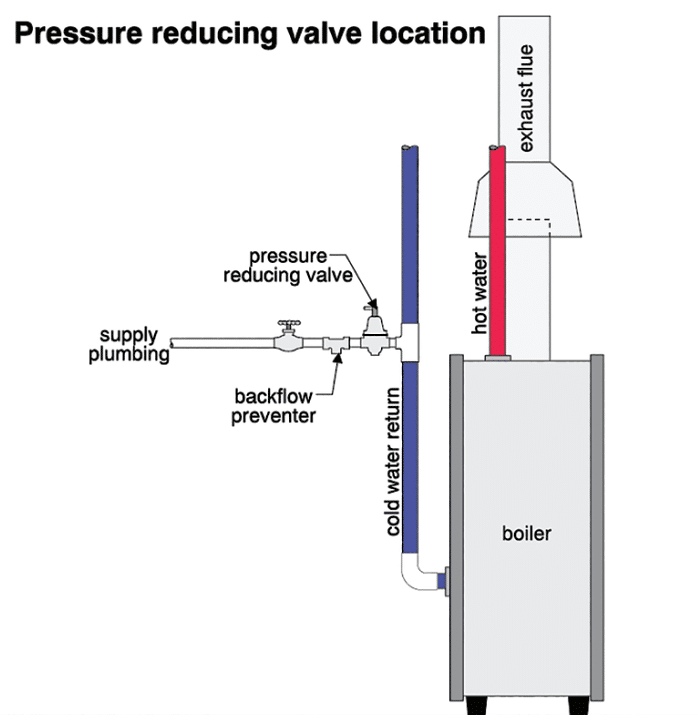

The valve is typically on a short connector pipe between the plumbing system and the boiler. The illustrations below [0858.jpg, 0862.jpg] show a pressure-reducing valve downstream of a backflow preventer. This is a common arrangement.

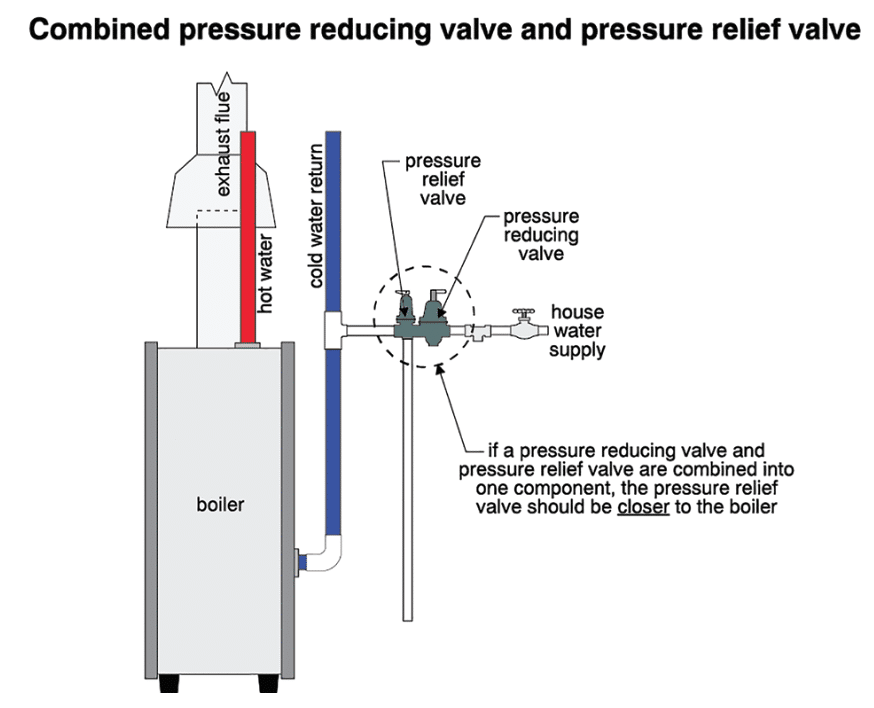

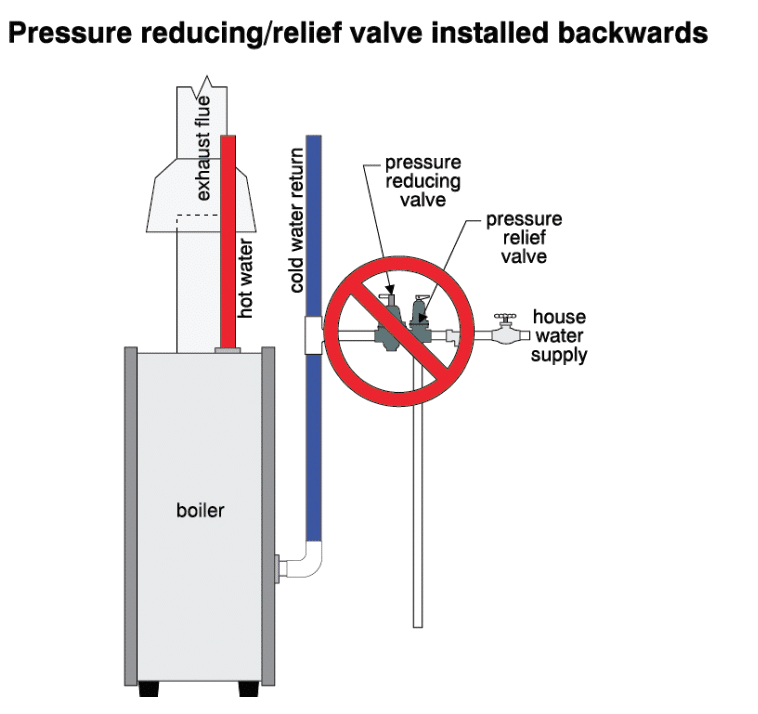

The pressure-reducing valve can also be part of an assembly that includes a pressure-reducing valve and a pressure-relief valve. When these two units are combined into one component, they are often referred to as a dual unit. The device should be installed so that the pressure-relief valve is closer to the boiler.

Note: The pressure-relief valve is often mounted on the boiler.

Also note: Boilers have single-purpose pressure-relief valves (PRVs). Water heaters have dual-purpose temperature/pressure-relief (TPR) valves.

Some pressure-reducing valves have an integral check valve that prevents water from flowing back from the heating system into the plumbing system. These eliminate the need for a separate backflow preventer, where permitted. Check to see what is common in your area and whether authorities having jurisdiction require a separate backflow preventer.

These valves are typically made of brass or steel and are very often shaped like a bell. There is no discharge pipe attached to a pressure-reducing valve because they are not intended to release water.

COMMON PROBLEMS

Valve set too low

Pressure-reducing valves are usually factory-set between 12 and 15 psi. Some are adjustable within this range and beyond (a range of 10-25 psi is common).

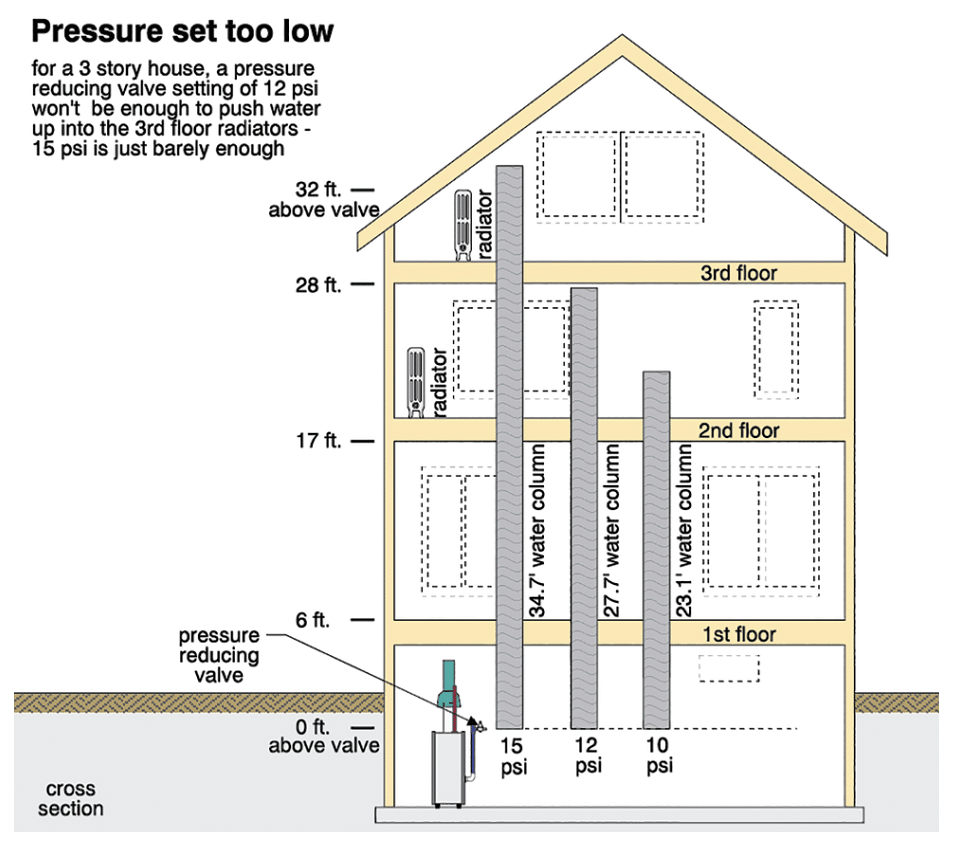

They are rarely faulty, but they may be set too low. A tall, three-story house with a basement may require a pressure-reducing valve set at more than 12 psi. The pressure at the boiler has to push water up to the top of the heating system. If the radiators on the upper floor are not filled with water, these rooms will be cold.

A pressure of 1 psi can push water up roughly 2.31 feet (about 28 inches). So, 10 psi can push a column of water up 23.1 feet; 12 psi (commonly available at pressure-reducing valves) can push water up about 28 feet (12 times 2.31). A pressure of 15 psi (the maximum for most pressure-reducing valves) can push water up about 34.5 feet.

Let’s look at that three-story house. It might be 5 feet from the pressure-reducing valve to the basement ceiling. The first floor may be 1 foot above the basement ceiling. If the height of the first floor is 11 feet (typical of Victorian homes), we are now 17 feet above the pressure-reducing valve.

Moving up through the 1-foot-thick floor system and then through a 10-foot-tall second floor adds another 11 feet. Now we’re 28 feet above the pressure-reducing valve. Moving through the 1-foot-thick third floor and approximately 3 feet above the floor to the top of the radiator adds another 4 feet. This brings us up to 32 feet.

As you can see, if the pressure-reducing valve is set at 12 psi (good for 28 feet), water may not fill the third-floor radiators. There should be enough pressure to fill the third-floor radiators and have at least 2 or 3 psi left over. If the valve is set at 15 psi (good for 34.5 feet), we should be all right, just barely.

Missing Valve

A missing pressure-reducing valve is an installation issue.

Pressure-reducing valves are not absolutely necessary and, in some jurisdictions, they are not commonly installed. They are an operating convenience. You can fill a boiler manually by opening a valve that connects the plumbing system to the heating system.

A pressure-reducing valve is a plus, but not a necessity. If you recommend adding one, make it clear that it’s an improvement rather than a repair.

Valve Leaks

Pressure-reducing valves may leak, of course. These photos show an example:

In the photo below, it is the backflow preventer that is dripping. It’s not fair to say that it’s leaking. It may be doing its job.

Inoperative Valve

The pressure-reducing valve can be inoperative in two different ways:

- The pressure-reducing valve may be obstructed or defective and no water may get through into the boiler.

- The pressure-reducing valve may have failed and the water pressure in the boiler system may be too high.

There may be a problem with the valve or dirt may be obstructing the valve. It’s also remotely possible the valve was installed backwards.

If the pressure-reducing valve doesn’t allow enough water through, the house won’t get warm enough, especially on the upper floors. The boiler will eventually run short of water and probably shut down on high temperature limit or low-water cut off.

If too much pressure is allowed through, the pressure-relief valve will operate constantly. If the pressure-relief valve isn’t working or is missing, there is a risk of a pressure build-up and a steam explosion.

The best way to determine whether the pressure-reducing valve is operating properly is to look at the temperature and pressure gauge on the boiler. When the boiler is cold, the pressure should be 12 to 15 psi. If the pressure is much lower than this, there may not be enough water in the system. If the pressure range is above this, the pressure-reducing valve may have failed.

High pressure may also result in the pressure-relief valve operating. Watch for a dripping pressure-relief valve pipe.

There are other causes of the boiler pressure being too high and the pressure-relief valve dripping. The expansion tank may be waterlogged or undersized, for example.

The temperature gauge may also be defective.

Valve Installed Backwards

Most pressure-reducing valves have an arrow indicating the proper direction of water flow through the valve. If the valve is installed backwards, the boiler will not get any make-up water. There is typically an arrow on the side of the valve pointing to the appropriate flow direction: the boiler.

A more serious implication is in the case of the combination pressure-reducing valve and pressure-relief valve. If the assembly is installed backwards, the boiler pressure-relief valve will be upstream of (before) the pressure-reducing valve. This puts the pressure-relief valve too far from the boiler and this important safety device may be compromised.

This is a rare installation defect with combination units, since the relief valve will typically release water (under the higher house pressure) when installed backwards. This should alert the installer that there is a problem. The release of water is due to the higher house pressure, generally well above the 30 psi setting. When the pressure-reducing valve/pressure-relief valve combination unit (dual unit) is installed backwards, the pressure-relief valve is sometimes found plugged because of the water release. This is a safety concern.

Summary

The pressure-reducing valve is an operating control rather than a safety control. Its job is to make sure the boiler has water in it at an appropriate pressure. Checking the pressure-reducing valve should be part of any hot-water heating system inspection.

To Read the Full Article

ASHI offers its members unparalleled resources to advance their careers. ASHI offers training for inspectors at all levels of knowledge and experience, including resources about all major home systems. Members benefit from a vast network of experienced professionals, providing a community for mentorship and knowledge sharing..

In this Issue

FIND A HOME

INSPECTOR

Professional Networking

Grow your professional network, find a mentor, network with the best, and best part of the community that’s making home inspection better every day.