Insulation Materials

Function

The purpose of insulation is to slow the rate of heat transfer. This is true in both hot and cold climates. In cold climates, it is intended to stop the flow of heat out of the building. In hot climates, its purpose is to slow the movement of heat into the building. Fortunately, insulation works in both directions. For the many climates in North America where heating and cooling are needed at different times of the year, insulation serves both functions.

Insulation doesn’t stop heat

We emphasize insulation only slows the movement of heat. It does not stop it entirely. What’s more, it isn’t the insulation material that stops most of the heat. The trapped air pockets within the insulation do most of the work. The solid material of the insulation does reduce direct radiation. Conduction and convection are controlled by still air.

Characteristics

The ideal insulation material would have the following characteristics:

- High resistance to heat flow (a high R-value)

- Inexpensive

- Durable (lasts the life of the home)

- Completely fills cavities

- Air barrier (stops air leaks)

- Vapor barrier (stops vapor diffusion)

- Moisture and rot-resistant (because all houses eventually leak)

- Non-combustible

- Chemically inert

Not surprisingly, no insulation meets all these criteria.

All materials add to R-Value

The insulation value of walls is more than the value of the insulation itself. All materials have some insulating value, including the plaster or drywall, polyethylene air/vapor barrier, wood sheathing, building paper, siding and the air films. However, the majority of the R-value of the wall is attributable to the insulation.

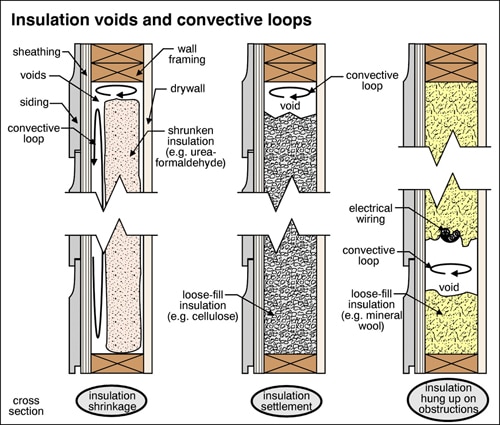

Insulation voids and convective loops

Gaps in insulation can dramatically reduce the R-value of a wall assembly. If insulation batts do not completely fill stud cavities side to side and top to bottom, convective loops can be established as the air moves freely through the stud cavity. Voids can allow a great deal of heat through the wall. It is important that voids are filled. Mineral wool and fiberglass batts can lose up to 30 percent of their R-value if there is a 4 percent gap in the insulation, measured over the exposed, insulated surface.

Heat loss through air movement

Typically, insulation is not designed to prevent heat loss from air leakage. Air sealing, including caulking and weather-stripping, reduces air leakage.

Forms of insulation

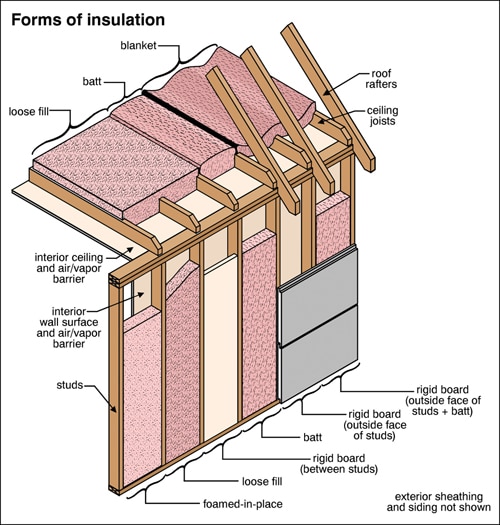

By and large, insulation takes one of four forms:

- Loose fill. Loose fill, which can be blown or poured, is common in roofs and walls. Materials such as cellulose fiber, glass fiber, mineral wool, vermiculite and perlite have all been commonly used. Other materials also may be found, including sawdust, wood shavings, shaved leather, asbestos and gypsum slag.

- Batts or blankets. Fiberglass and mineral wool commonly come in batts or blankets. Batts typically are 12 to 24 inches wide and fit between ceiling joists, rafters and wall studs. Blankets can be up to six feet wide and typically are laid over ceiling joists.

- Rigid boards. Rigid board insulation can be fit between studs or on the outer face of studs, replacing exterior sheathing. Common board insulations include fiberglass, expanded polystyrene, extruded polystyrene, polyurethane and polyisocyanurate. These materials often are faced with housewrap-type products, kraft paper, asphalt-impregnated kraft paper or aluminum foil. Some of these materials have very high R-values.

- Foamed-in-place insulations. Foamed-in-place insulations are becoming more popular. They include polyurethane and polyisocyanate. Notice it’s similar to the word polyisocyanurate, but we left out the “ur” on purpose.

Image: Foamed-in place insulation commonly used to increase R-Value.

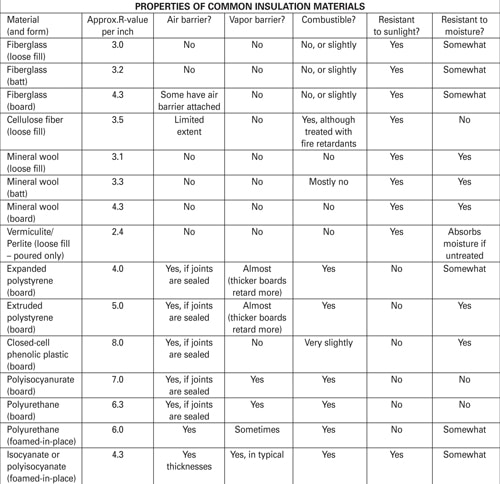

Common insulation materials and their properties

We’ve talked about some of the desirable features of insulation materials. The chart below (PDF of the chart) sets out the properties of various insulating materials. Some of the information in the chart has been approximated and there are exceptions to these numbers. We understand there are variances with each material, depending on density and other factors, but this is a broad guideline. Now, let’s look at some of the insulation materials.

Fiberglass: Fiberglass is a commonly used, versatile, inexpensive insulation. The glass itself is not combustible, although the binders used in it may be. Fiberglass may have an air/vapor retarder fixed to the surface, which could be kraft paper, foil, vinyl or a housewrap.

Mineral wool: Mineral wool insulation is similar to fiberglass. It is made with slag or rock spun into a wool. Typically treated with oil to reduce the dust, and with binders to hold it together, it is non-combustible, water-resistant, rot-resistant and inexpensive.

Cellulose: Cellulose is shredded newspaper, chemically treated to resist fire, rot and fungus and to prevent corrosion when wet. Cellulose is denser than fiberglass and therefore provides a better air barrier than fiberglass. Cellulose is less susceptible to wind-washing and convective air movement through the insulation itself. 44

Vermiculite or perlite: Vermiculite is expanded mica, and perlite is a rock similar to granite. Perlite, when expanded, takes on a popcorn-like appearance. Vermiculite, when expanded, becomes small, light cubes.

Image: Vermiculite insulation commonly used in attics

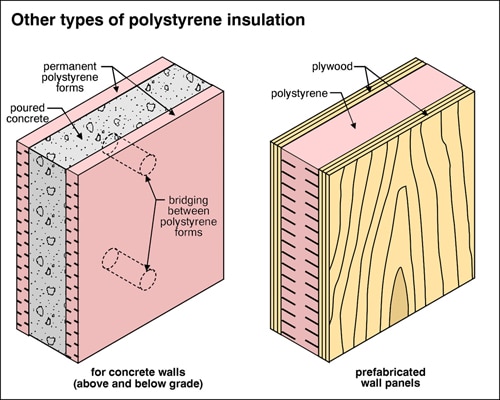

Polystyrene: Polystyrene insulation is a combustible plastic. It comes in two common forms:

- Expanded polystyrene or beadboard is made by compressing small beads of plastic together to form a board. Typically white, it has a makeup similar to foam coffee cups.

- Extruded polystyrene is a closed-cell insulation material. The beadboard has balls of foam surrounded by air. Extruded polystyrene has balls of air surrounded by foam.

Concrete Forms: Polystyrene also can be used as permanent forms for poured concrete, both above and below grade. This provides a concrete wall with good insulating value.

Urea-Formaldehyde Foam Insulation (UFFI)

This type of insulation deserves special attention because it has been controversial.

Urea-formaldehyde foam insulation, or UFFI (pronounced “you-fee”), was a common retrofit insulation in the 1970s. In general, it was injected as a mixture of urea-formaldehyde resin, an acidic foaming agent, and a propellant such as air. For the most part, it was used in existing houses, most often injected into wood-frame wall cavities or other areas where installation of conventional insulation was impractical.

Holes in the wall may have been used to insert UFFI insulation in this brick home.

UFFI has been studied extensively and there is no evidence of any health issues.

From a real estate value standpoint, UFFI may have an impact in your working area; however, our research has not convinced us of any reason a homeowner should have any UFFI-related health concerns.

Summary

We have introduced the function of insulation, the forms, common insulation materials and their properties. There is much more to learn about this system of a home. Greater details on the material types, common deficiencies, strategies for inspecting and implications can be found in the ASHI@Home training program.

Glossary

Conduction: The transfer of heat between substances that are in direct contact with each other. Conduction is slowed by insulation.

Convection: The transfer of heat by the circulation or movement of the heated parts of a liquid or gas. Convection can be interrupted by a physical barrier.

Radiation: Radiation is electromagnetic waves that directly transport heat energy through space. Heat energy transferred through radiation can be interrupted by a material that reflects it.

Air films: The air space that exists within the wall assembly that adds to the insulation value of the wall.

About ASHI@Home

This article is from the ASHI@Home education system, a comprehensive distance-learning program developed with ASHI by one of the most respected names in training and professional home inspection — Carson Dunlop. Together, we have integrated a wealth of experience and expertise into a self-paced, comprehensive set of 10 courses that you can complete in the comfort and convenience of your own home.

This program goes far beyond an introduction to home inspection, providing career training that prepares you for success in the home inspection profession. Also, individual modules are approved for ASHI CE credits. Choose the printed version or the ASHI online learning program. Call 800-268-7070, Ext. 251, to learn more.

To Read the Full Article

ASHI offers its members unparalleled resources to advance their careers. ASHI offers training for inspectors at all levels of knowledge and experience, including resources about all major home systems. Members benefit from a vast network of experienced professionals, providing a community for mentorship and knowledge sharing..

In this Issue

FIND A HOME

INSPECTOR

Professional Networking

Grow your professional network, find a mentor, network with the best, and best part of the community that’s making home inspection better every day.